KTC838A Automatic Tension Controller with Radius

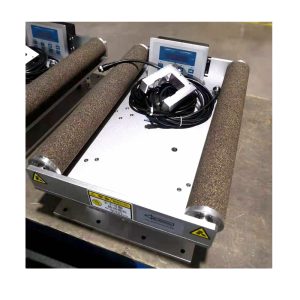

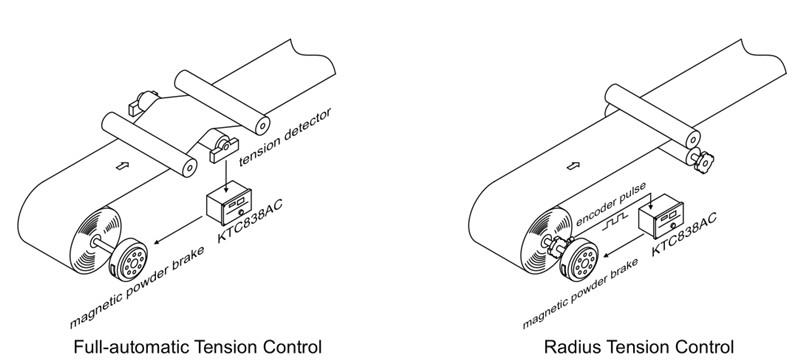

The full-automatic tension controller KTC838A is a high-precision, multi-functional, fully digital intelligent tension controller. It can cooperate with the tension detector to form a closed loop tension control system, or form an open loop tension control system by automatically calculating the tension through a proximity switch/encoder. That is, it has the functions of KTC818A and KTC828A at the same time, providing users with more free choices.

Description

Automatic Web Tension Controller KTC838A with Radius:

The full-automatic tension controller KTC838A is a high-precision, multi-functional, fully digital intelligent tension controller. It can cooperate with the tension detector to form a closed loop tension control system, or form an open loop tension control system by automatically calculating the tension through a proximity switch/encoder. That is, it has the functions of KTC818A and KTC828A at the same time, providing users with more free choices.

Features

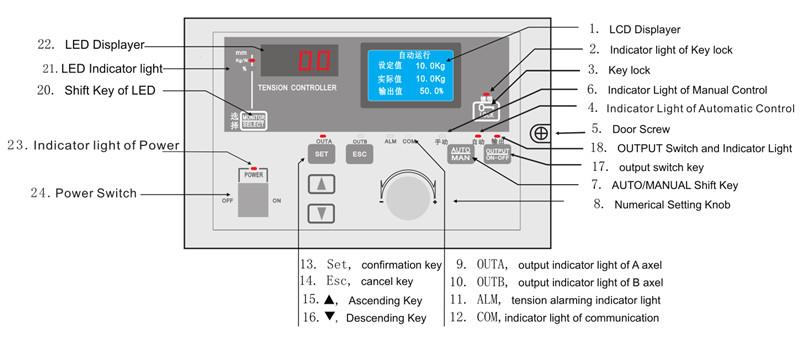

1. 128×96 graphic LCD is adopted, with Chinese and English display options, and the operation interface is friendly.

2. Digital design, no adjustable potentiometer, simple tension calibration process, accurate, stable and reliable tension measurement.

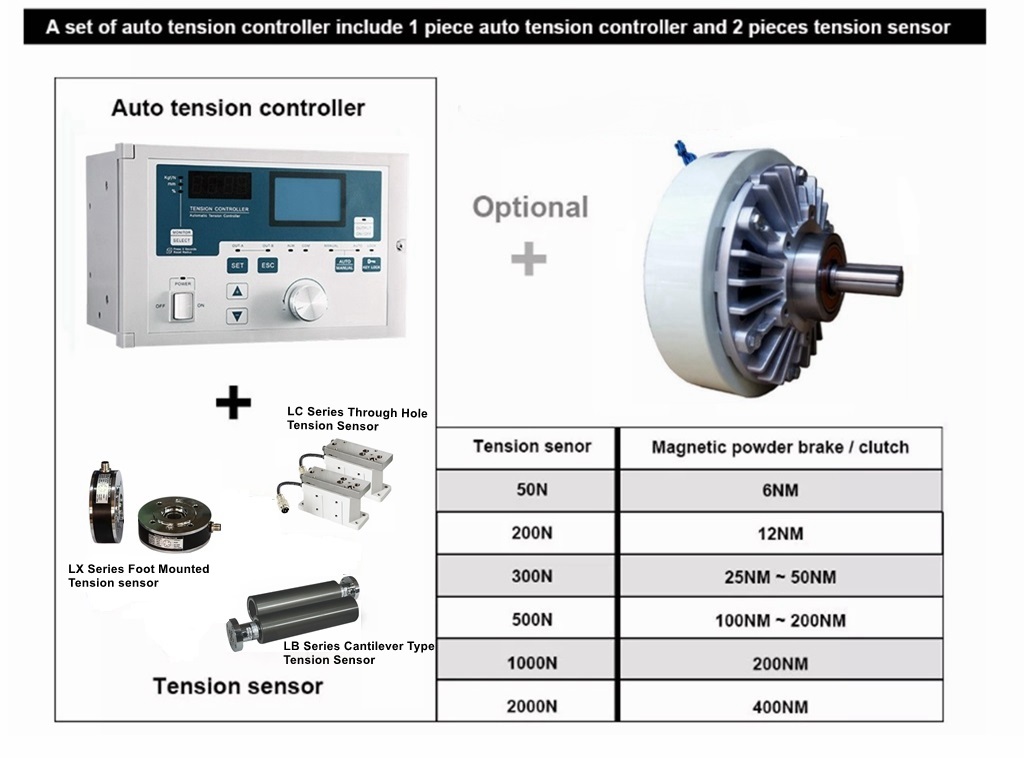

3. It can receive input signals from single/dual sensors and adapt to various tension sensors as input signals:

a. Differential special tension sensor can be selected (input signal range is 200mV, power supply is 5V)

b. Strain gauge tension sensor can be selected (input signal range is 20mV, power supply is 10V)

c. Angle potentiometer can be used as floating roller tension control.

4. It can realize the taper tension control function, support the thickness accumulation, and measure the roll diameter by the ratio method.

5. Optional serial communication function, optional RS485 communication interface, PLC and PC form a distributed system (optional communication function).

6. PID algorithm without overshoot is adopted to ensure no overshoot of tension during system startup/shutdown.

7. It has dual axis switching function and acceleration/deceleration control function.

8. Automatic/manual control undisturbed mode switching.

9. Parameter password protection to prevent incorrect modification.

10. The switching power supply (165-264VAC) with strong adaptability is adopted to ensure long-term reliable operation.

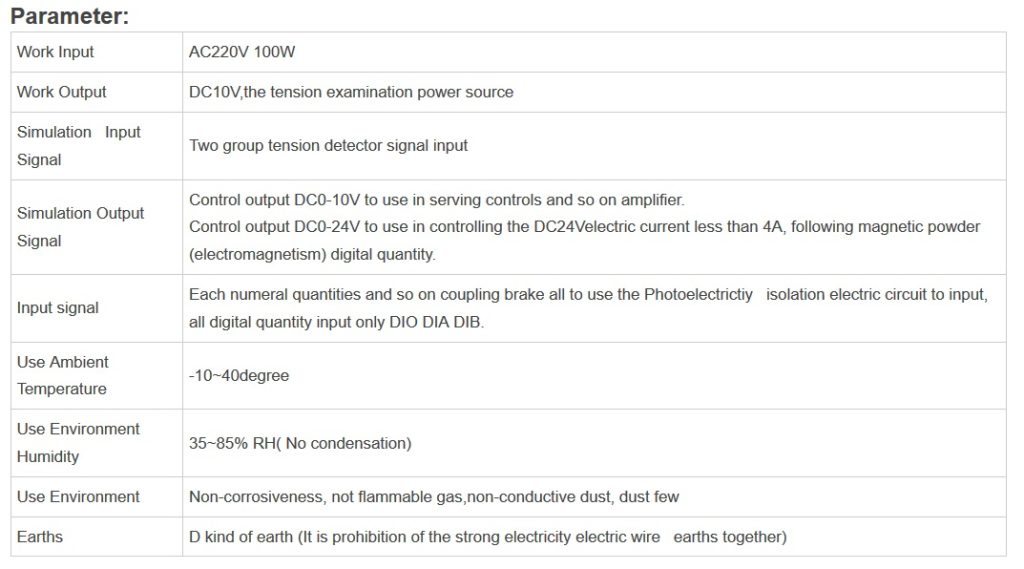

Drawing & Specifications

Automatic Tension Controller KTC838A with Taper and Communication Function

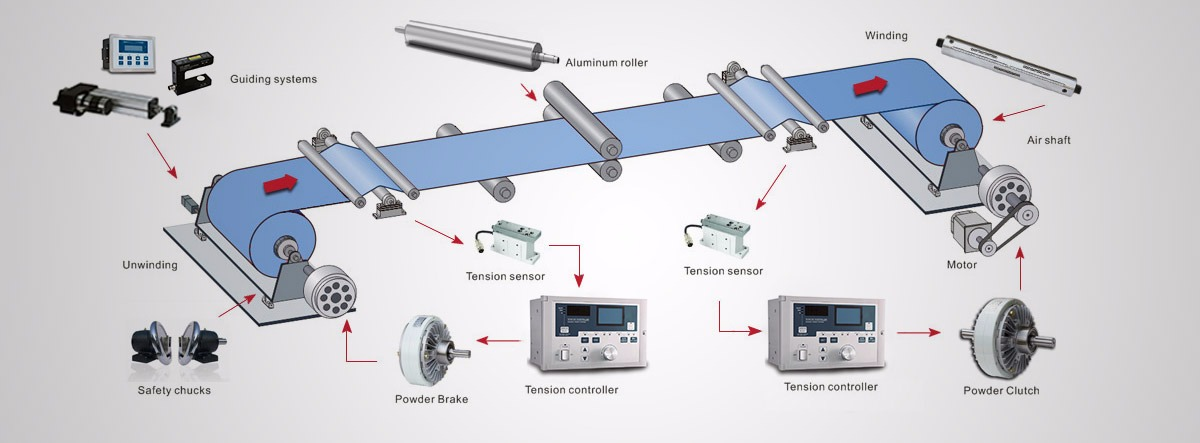

KTC-838A tension controller adopts a new graphic LCD display, which can display more clearly in Chinese and English. It sends out a 0~24VDC control voltage command for magnetic particle clutch/brake, and can also output a 0~10V voltage signal to control the inverter, servo motor or other actuators to conduct high-precision tension control on the coil. It is widely used in printing, packaging, paper making, cable, rubber and plastic, electronic battery, textile printing and dyeing and other industries.

Operating panel

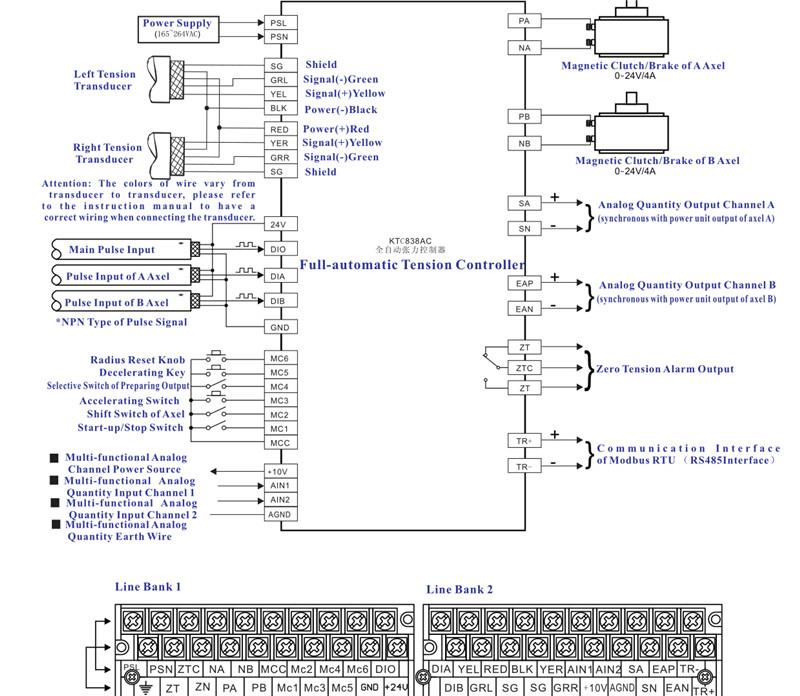

Wiring Diagram

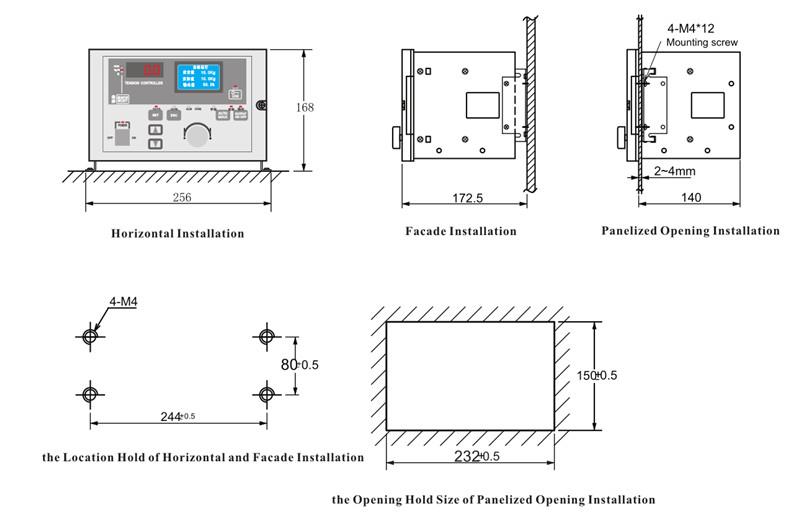

Mounting

Packing & Delivery

| Item Name | Automatic Tension Controller KTC838A with Radius |

| MOQ(Minimum Order Quantity) | 1pc |

| Lead time | 1-2 days after receiving the deposit |

| Calculated Packing Size | 20cm*15cm*15cm,2kg/pc |

| Package | Carton |

| Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,Western Union |

| Country of Origin | China |

Application

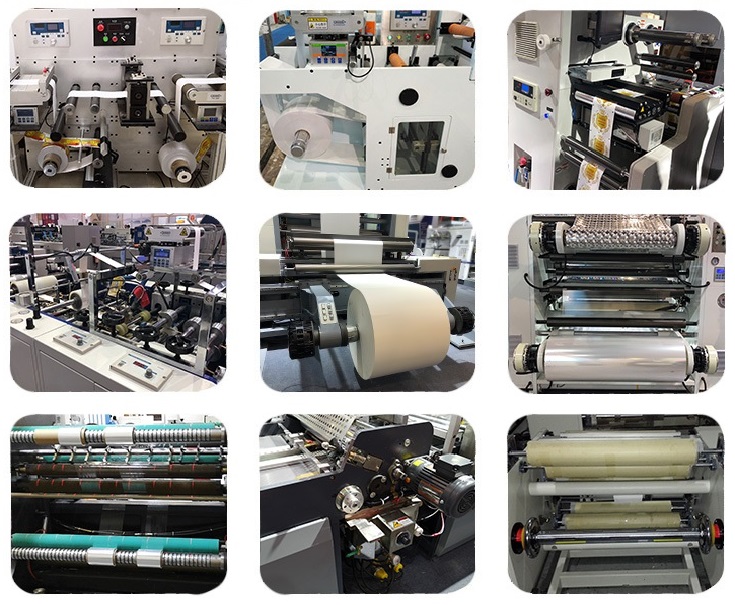

It is applicable to constant tension control system, such as printing machine, slitting machine, compound machine, coating machine, paper machine, wire drawing machine and cable winding machine, as well as metal sheet, strip, film and other processing equipment and textile machinery.

Inquiry

FAQ

1. When can I get the quotation?

We usually quoted within 24 hours after receiving your inquiry. If you are very urgent to get the price, please call us or tell us in your email, so that we can regard your inquiry priority.

2. How should I place the order?

For all in one web guide system, please kind tell us your material max width and which materials, so we will recommend suit model with drawing.

For Servo Linear Web Guide Control System, please kind tell what material and pushing stroke with pushing torque/weight.

For air shaft and roller, please show us your drawing, or let us know your request, and then we will provide you drawing for confirmation.

For powder clutch, powder brake, air clutch, air brake, and safety chucks, please let us know the model number based on our specs.

3. What’s your MOQ basis?

Normally, we don’t have MOQ request, except the rollers.

4. What about the lead time for production?

Honestly, it depends on the order quantity and the type of our products. For powder clutch, powder brake, tension controller, load cell and edge position controller which is about 3-5 days. For safety chucks, air shaft and roller which need about 5-15days

5. What is the term of delivery?

We can arrange with EXW, FOB, CIF…etc. You can choose the most convenient one or cost-effective way.