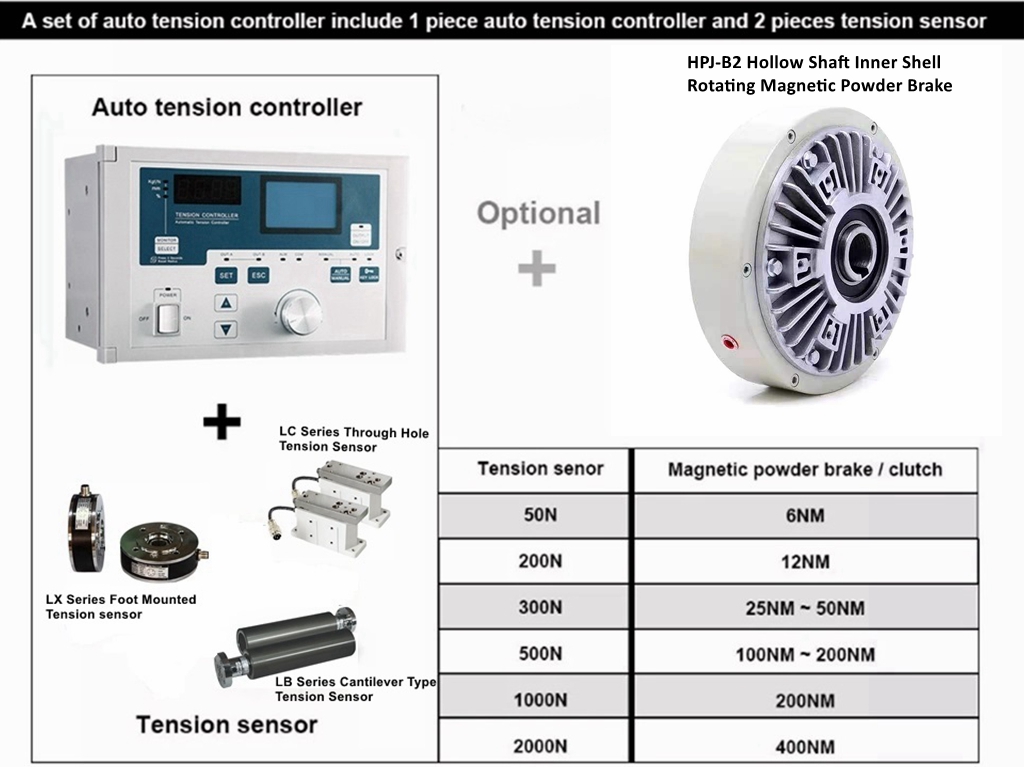

Hollow Shaft Inner Shell Rotating 24V industrial clutch brake Magnetic Powder Brake

It can transmit a certain torque when it is independent of the slip, and has the advantages of fast response, simple structure, no pollution, no noise, no impact and vibration, energy saving, etc. It is a multi-purpose, high-performance automatic control element.

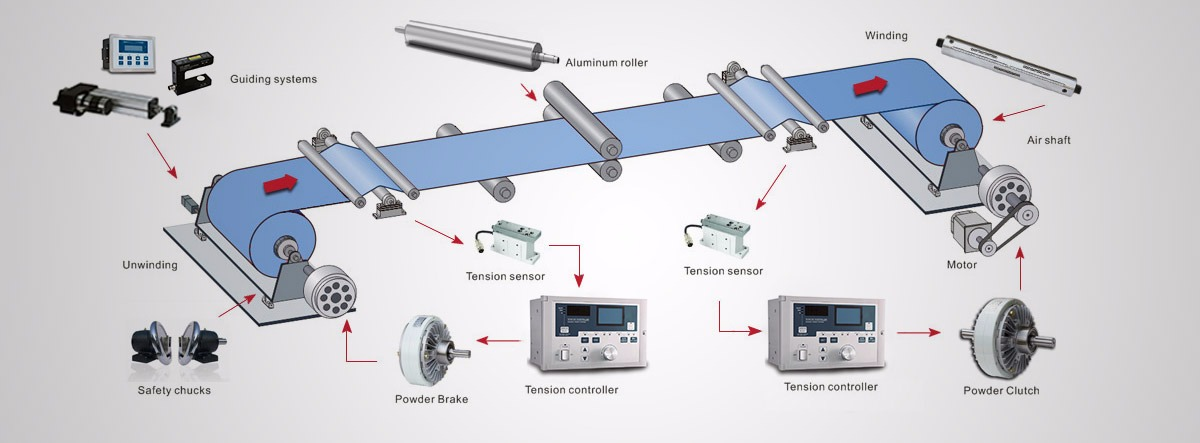

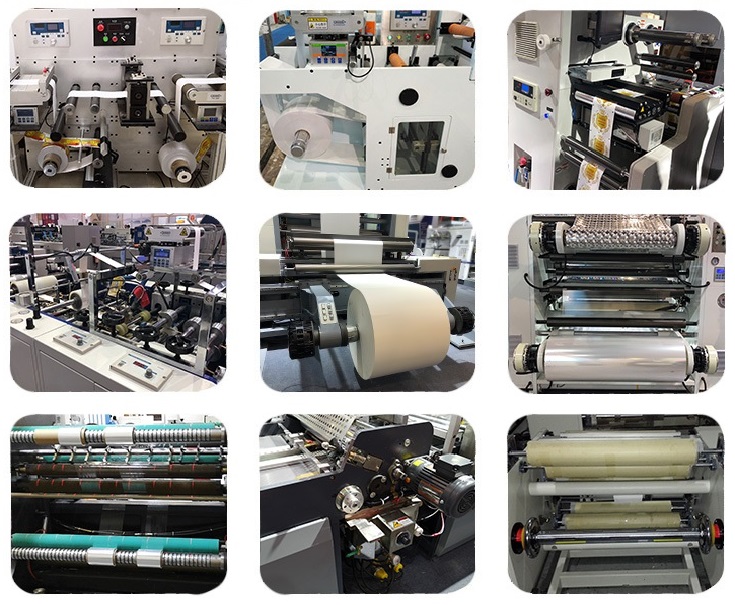

It has been widely used in paper making, printing, plastic, rubber, textile, printing and dyeing, wire and cable, metallurgy and other related coiling processing industries for unwinding and winding tension control

Description

HPJ-B2 Hollow Shaft Inner Shell Rotating Magnetic Powder Brake

| Brand Name: | HPJ-B2 Series |

| Application: | For all kinds of printing & converting machines need unwinding |

| Voltage | 24V DC |

| MAX Rotation Speed | 1000rpm/min(6N.m~50N.m);800rpm/min(100N.m~200N.m) |

| Rated Torque | 0.6kgfm–40kgfm |

| Current | 0.8A-3A |

| Colour: | White |

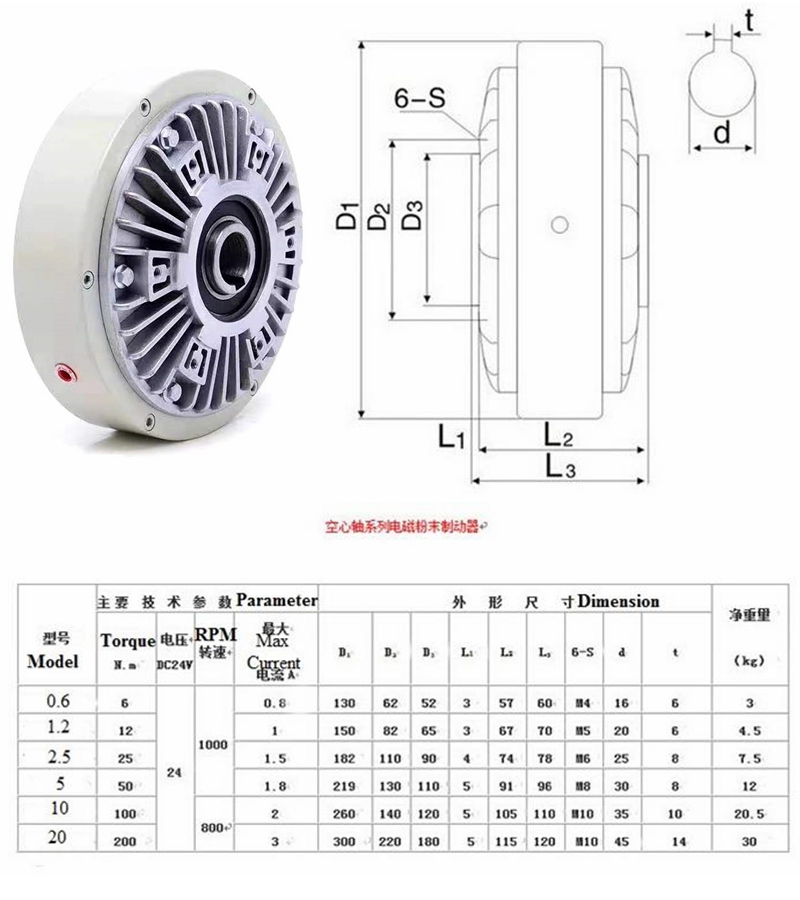

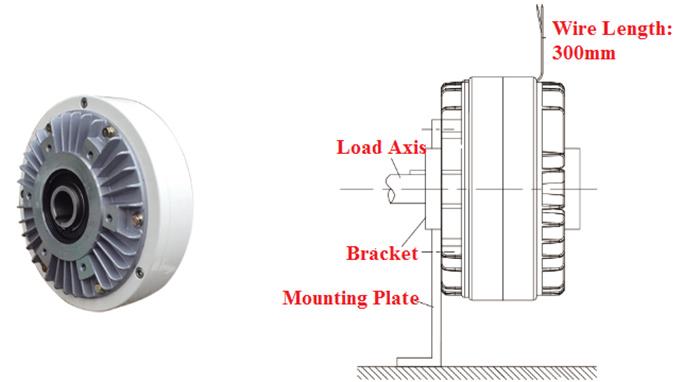

Drawing & Specifications

HPJ-B2 Hollow Shaft Inner Shell Rotating Magnetic Powder Brake

It has been widely used in paper making, printing, plastic, rubber, textile, printing and dyeing, wire and cable, metallurgy and other related coiling processing industries for unwinding and winding tension control.

Magnetic powder brake is based on electromagnetic principle and uses magnetic powder to transmit torque. It has the characteristics that the excitation current and the transmission torque are basically linear. It can transmit a certain torque when it is independent of the slip, and has the advantages of fast response, simple structure, no pollution, no noise, no impact and vibration, energy saving, etc. It is a multi-purpose, high-performance automatic control element. It has been widely used in paper making, printing, plastic, rubber, textile, printing and dyeing, wire and cable, metallurgy, tablet press and other related coiling processing industries for unwinding and winding tension control. Magnetic powder brake is also often used for dynamometer loading and braking of transmission machinery.

Catalogue:

HPJ-B2 Model: 0.6N.m ,3N.m,6N.m,12N.m,25N.m,50N.m,100N.m 200N.m 400N.m,800N.m;

characteristic

1. Continuous sliding operation can be achieved.

2. Stable torque can be obtained.

3. No beep. The sluggish phenomenon of the action surface will occur in the friction mode, but it will not occur here, and it will not produce a connecting sound, so the operation is quite quiet.

4. High heat capacity. Due to the use of magnetic powder with superior heat resistance and the use of ideal cooling method, even if the continuous sliding operation is too harsh, it can be used with ease.

5. Smooth continuous and driving state can be achieved. Since the static friction coefficient is almost the same as the dynamic friction coefficient, there will be no vibration when fully connected, and the speed can be increased or decreased according to the load.

The type selection of magnetic particle brake is generally based on the maximum torque required to be transmitted, and attention shall be paid to ensuring that the actual slip power is less than the allowable slip power of magnetic particle clutch and brake.

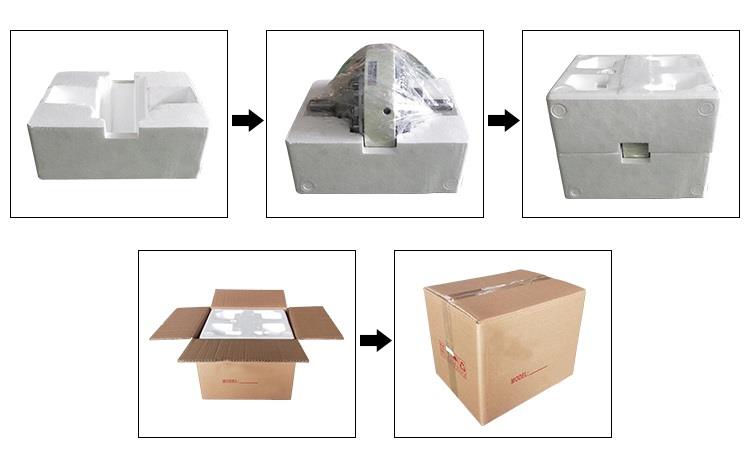

Packing & Delivery

| Item Name | HPJ-B2 Hollow Shaft Inner Shell Rotating Magnetic Powder Brake |

| MOQ(Minimum Order Quantity) | 1Pc |

| Lead time | 3-5 days after receiving the deposit |

| Calculated Weight | According to different models |

| Package | Carton/Wooden Box |

| Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Application

It can transmit a certain torque when it is independent of the slip, and has the advantages of fast response, simple structure, no pollution, no noise, no impact and vibration, energy saving, etc. It is a multi-purpose, high-performance automatic control element. It has been widely used in paper making, printing, plastic, rubber, textile, printing and dyeing, wire and cable, metallurgy, tablet press and other related coiling processing industries for unwinding and winding tension control. Magnetic powder brake is also often used for dynamometer loading and braking of transmission machinery.

Inquiry

FAQ

1. When can I get the quotation?

We usually quoted within 24 hours after receiving your inquiry. If you are very urgent to get the price, please call us or tell us in your email, so that we can regard your inquiry priority.

2. How should I place the order?

For all in one web guide system, please kind tell us your material max width and which materials, so we will recommend suit model with drawing.

For Servo Linear Web Guide Control System, please kind tell what material and pushing stroke with pushing torque/weight.

For air shaft and roller, please show us your drawing, or let us know your request, and then we will provide you drawing for confirmation.

For powder clutch, powder brake, air clutch, air brake, and safety chucks, please let us know the model number based on our specs.

3. What’s your MOQ basis?

Normally, we don’t have MOQ request, except the rollers.

4. What about the lead time for production?

Honestly, it depends on the order quantity and the type of our products. For powder clutch, powder brake, tension controller, load cell and edge position controller which is about 3-5 days. For safety chucks, air shaft and roller which need about 5-15days

5. What is the term of delivery?

We can arrange with EXW, FOB, CIF…etc. You can choose the most convenient one or cost-effective way.