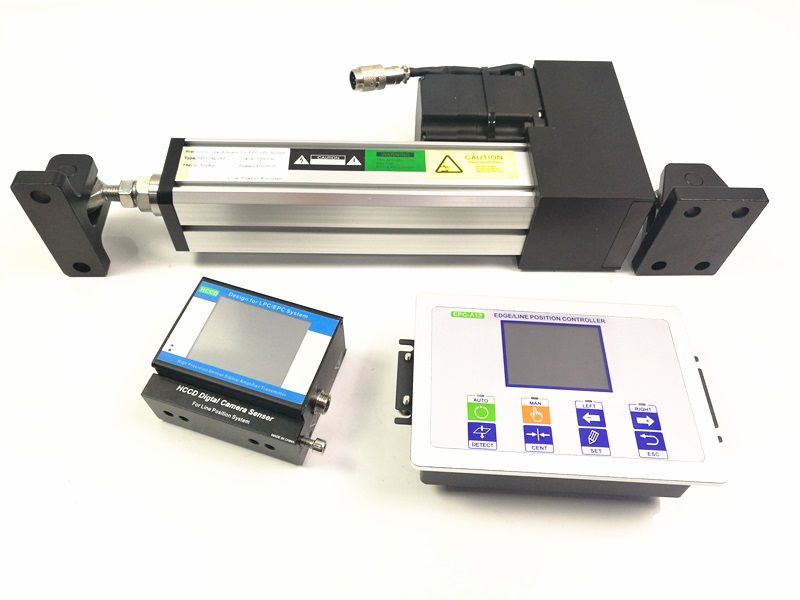

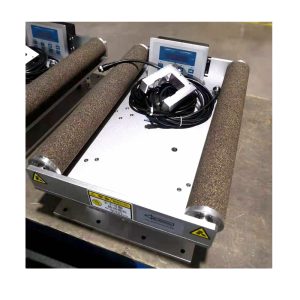

EPC-A10/A12 web guide controller PD803L200 set web guide system Edge position control system

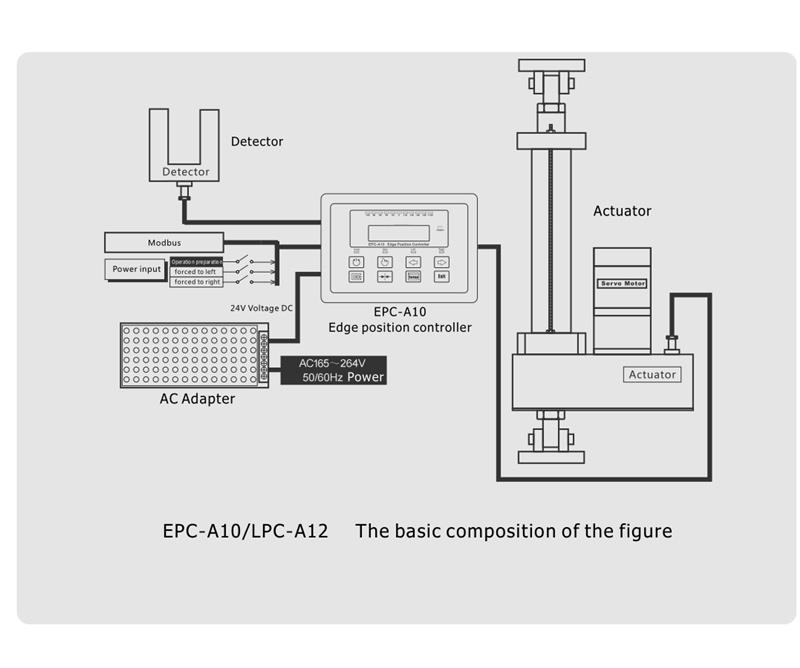

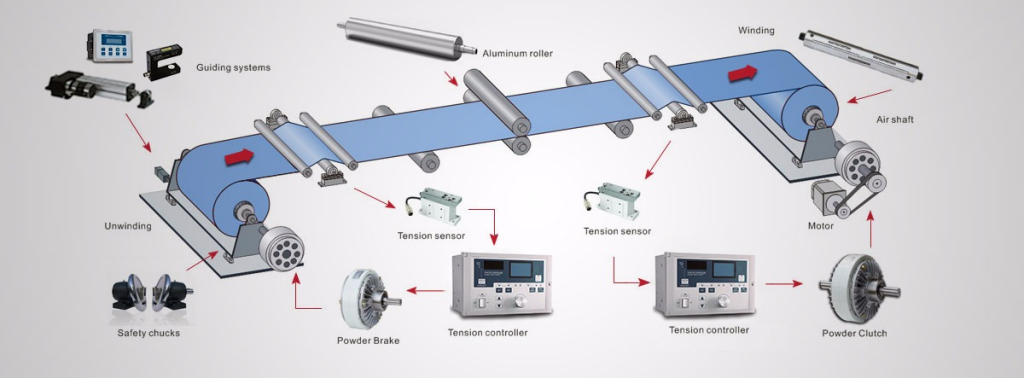

Edge position control system can connection many differeny type of sensor and actuator,support web control(EPC),follow line control(LPC) chase center control (CPC),stagger contorl(SPC).

Use large color screen touch screen as human-machine interface,easy to operate,beautiful,with a setup wizard and the online help system,even if for the first time using this system,can easily complete the basic setup.

Description

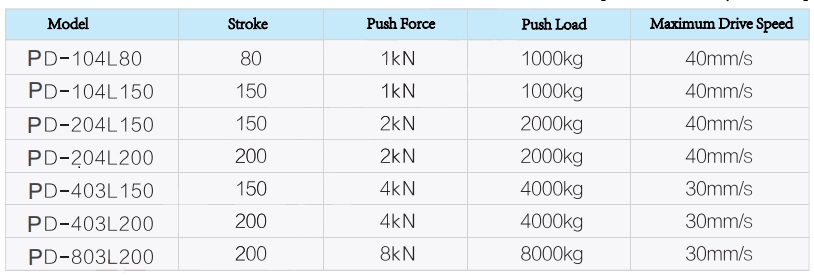

Web guide control system PD Series :

Most of PD-803L200 parts are die casting production, precision machining, compact and reasonable structure, beautiful appearance, good mechanical strength, complete connection accessories, core materials and some materials are made of high quality foreign materials to ensure quality. Years of use proves that the installation is convenient, the transmission is reliable, the operation is stable, the wear is small, the service life is long, and the product is very mature.

1. The base structure, free to move 15 degrees in the vertical direction

2. Precision ball screw

3. With a limit switch, midpoint switch

4. Working voltage Ac220v

5. Servo motor

6. Drive stroke 80mm

7. The maximum thrust 1KN

8. Driving speed 10mm / sec

Web guide system Specification:

| Control Method | DC Servo Driver |

| Power | DC 24V /5A |

| Control Input | DC 0~5A |

| Control output | 24V, PWM |

| Response time | 0.5 mS |

| Environment temperature | -10~60°C, below RH90% |

| Weight | 1.2 kg |

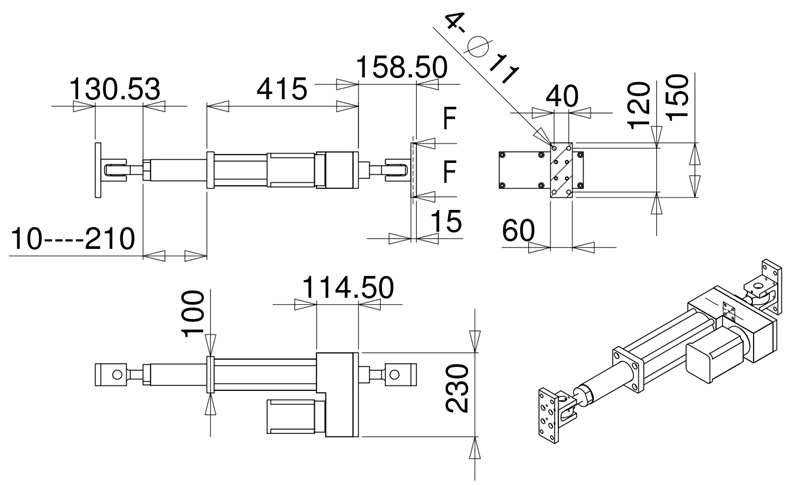

Drawing & Specifications

Web alignment Guiding System PD803L200

Packing & Delivery

| Item Name | PD-803L200 Web Guide System |

| MOQ(Minimum Order Quantity) | 1Set |

| Lead time | 2-3 days after receiving the deposit |

| Calculated Packing Size | 60cm*20cm*15cm,25kg/set |

| Package | Carton/Wooden Box |

| Price Term | EXW,FOB, CIF, etc |

| Payment term | TT, L/C,Western Union |

| Country of Origin | China |

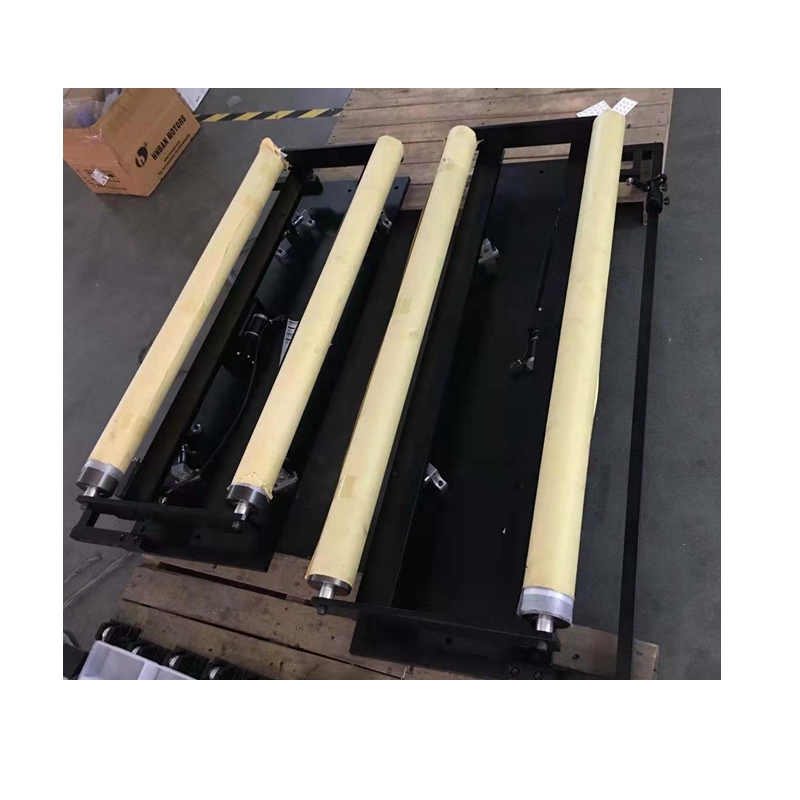

Application

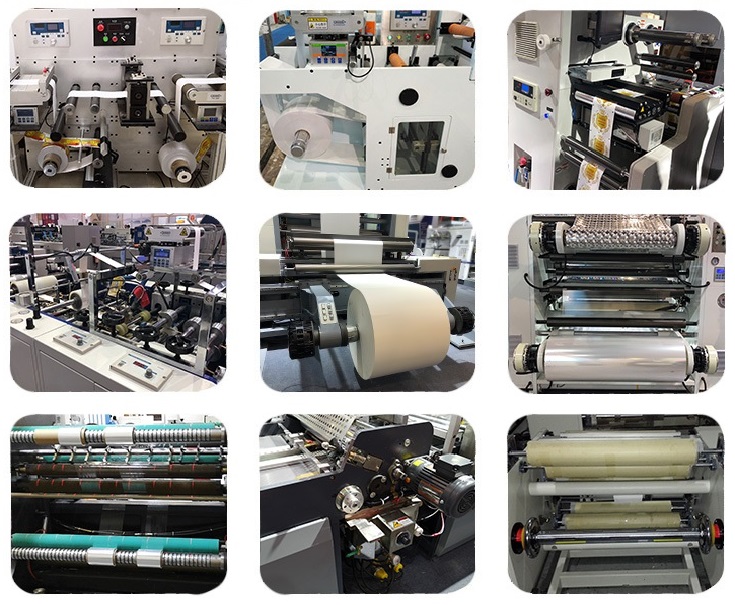

The correction system refers to the technical operation adopted by the manufacturer to keep the sides of the coil neat and consistent during spraying, printing, punching, laminating, slitting or other coil winding processes. It is widely used. It has brought great benefits to the industry. Correction control has led to the emergence of industries such as steel, corrugated paper, textile, printing, labeling, labeling, paper, plastic film, building materials, cables, rubber, tires, and non-woven corrugated paper processing. Automatic control.

Inquiry

FAQ

1. When can I get the quotation?

We usually quoted within 24 hours after receiving your inquiry. If you are very urgent to get the price, please call us or tell us in your email, so that we can regard your inquiry priority.

2. How should I place the order?

For all in one web guide system, please kind tell us your material max width and which materials, so we will recommend suit model with drawing.

For Servo Linear Web Guide Control System, please kind tell what material and pushing stroke with pushing torque/weight.

For air shaft and roller, please show us your drawing, or let us know your request, and then we will provide you drawing for confirmation.

For powder clutch, powder brake, air clutch, air brake, and safety chucks, please let us know the model number based on our specs.

3. What’s your MOQ basis?

Normally, we don’t have MOQ request, except the rollers.

4. What about the lead time for production?

Honestly, it depends on the order quantity and the type of our products. For powder clutch, powder brake, tension controller, load cell and edge position controller which is about 3-5 days. For safety chucks, air shaft and roller which need about 5-15days

5. What is the term of delivery?

We can arrange with EXW, FOB, CIF…etc. You can choose the most convenient one or cost-effective way.