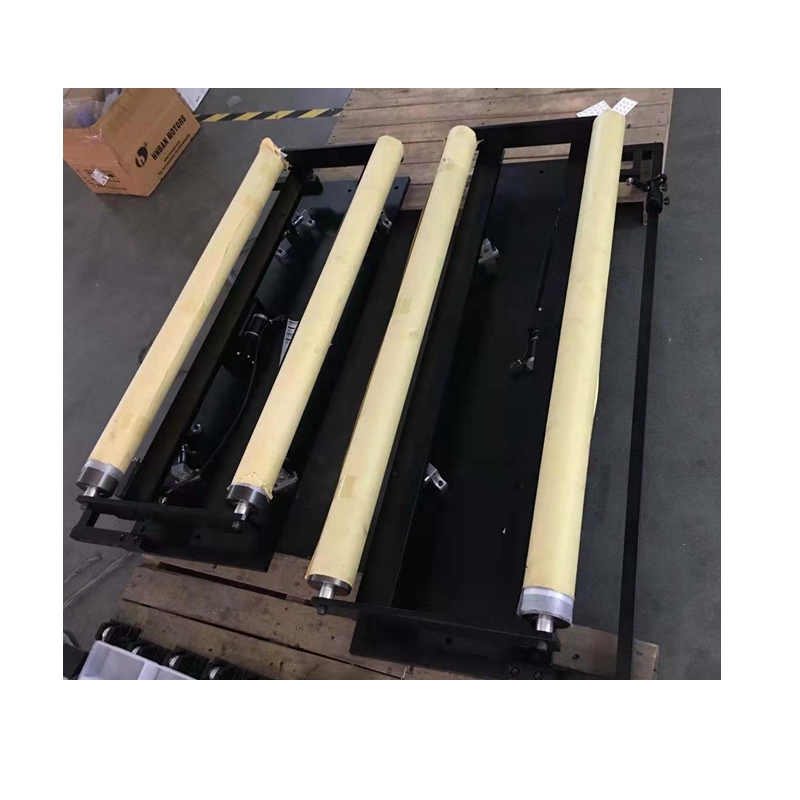

1000mm width web guiding system servo motor drive Aligner System

- Web guide system Product Features:

- 1. Brushless DC servo motor driving, maintenance free;

- 2. Accuracy ball screw bar and accuracy positioning;

- 3. With large guiding travel;

- 4. Roller length and width can be custom made;

- 5. Roller surface treatment can be anodized, rubber and cork leather;

- 6. Manual or air fixture of the cutting station is optional.

Description

All-in-one web guide control system PG Series :

Our Newly developed all-in-one web guide controller is applied to accurate correct the narrow range of materials. Especially for label printing, packaging and non-woven industries. All-in-one web guiding controller is with compact design, easy installation and saving space. Controller, driver and detector are integrated which help user to increase high efficiency during installation and debugging.

Web guide system Product Features:

Features:

1. Support three operation modes: edge-following, line-following and center-alignment.

2. Support photoelectric sensor, ultrasonic transducer and CCD Sensor

3. Detect sensor’s parameters intelligently, no need to correct the sensor under most circumstances

4. Automatic travel measurement, no need to limit the switch mechanically.

5. No overshot integral variable PI algorithm, high accuracy, fast reaction and less error.

6. 0.5mS super-speed of responding

7. Analog quantity transducer signal 12bit AD sampling, 700,000 times of sampling per second

8. Adopt FIR digital filter and return difference filter, stronger anti-interference capability and more stable signal

9. DC servo motor to push the ball screw

10. Power-down memory of all the parameters at any states in the system

11. Store 10 groups of parameters from different material, convenient and efficient switchover of material

12. Simplified Chinese/ Traditional Chinese /English for menu operation

13. Humanized operation, fast, simple and convenient

14. Support Modbus and PLC/Human-computer networking control

Web guide system Specification:

| Power supply | DC24V~45V, stand 36V |

| CPU Processor | 32-bit CPU main Frequency>72M |

| Rectification Algorithm | No Overshot Integral Variable PI Algorithm |

| Analog input | 3 channel 0~6V, impedance 20K |

| Sensor voltage | DC12V ,350mA Max |

| Response time | 0.5ms |

| Analog input resolution | 12 bit ADC |

| Switch contacts input | 3 channel NPN |

| Web control mode | EPC, LPC, CPC, SPC |

| Support the sensor type | Ultrasonic sensors, photo sensor, CCD sensor |

| Actuator speed | 14mm/s~40mm/s can adjust |

| Actuator thrust | 100Kgf/200Kgf/400Kgf/800Kgf |

| ESD protective | IEC1000-4-2,±15KV(Air),±8KV(Contact) |

| Screen display | 2.8″,260K colors TFT |

| Motor drive | Brushless DC servo motor to drive |

| Levels of protection | Ip53 |

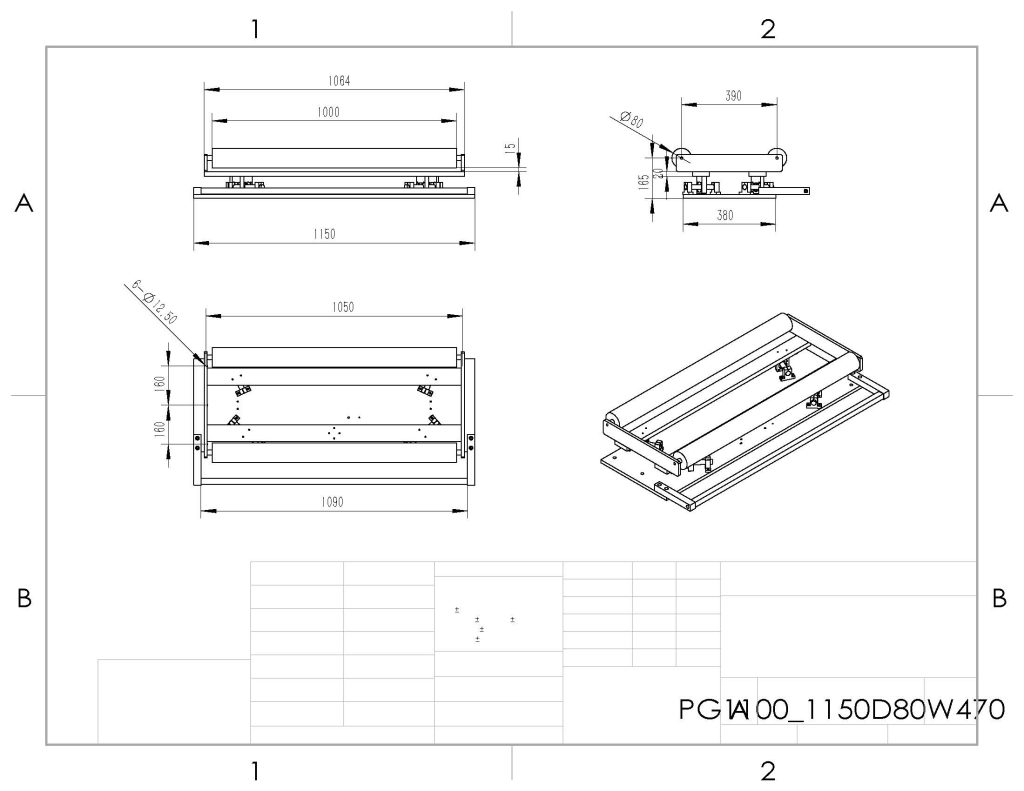

Drawing & Specifications

1000mm width web alignment Guiding System PG-1000A

| Model | 1100mm Web Displacement Guide System |

| Roller Diameter | 80mm(can be customized) |

| Roller Length | 950mm(Different models have different roller length) |

| Web Width Range | 200mm-970mm |

| Guide Angle | ±15° |

| Maximum Tension | |

| Power Input | AC220V/80W |

| Span Between 2 Rollers | 390mm(can be customized) |

| Maximum Drive Speed | 40mm/s |

| Environment Temperature | -10~60℃/below RH90% |

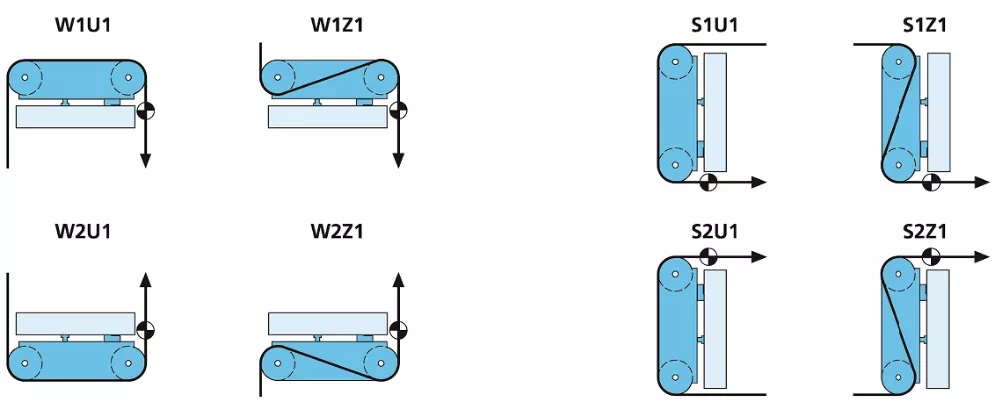

PG series material moving direction

Packing & Delivery

| Item Name | PG-1000A Offset Pivot Guide |

| MOQ(Minimum Order Quantity) | 1pc |

| Lead time | 6-9 days after receiving the deposit |

| Calculated Packing Size | 115cm*55cm*45cm/120kg/pc |

| Package | Wooden box |

| Price Term | EXW,FOB, CIF, etc |

| Payment term | TT, L/C,Western Union |

| Country of Origin | China |

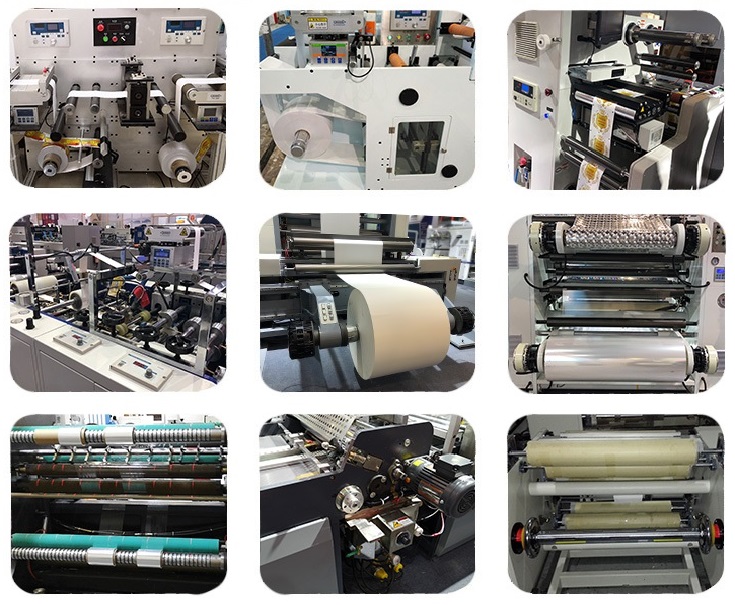

Application

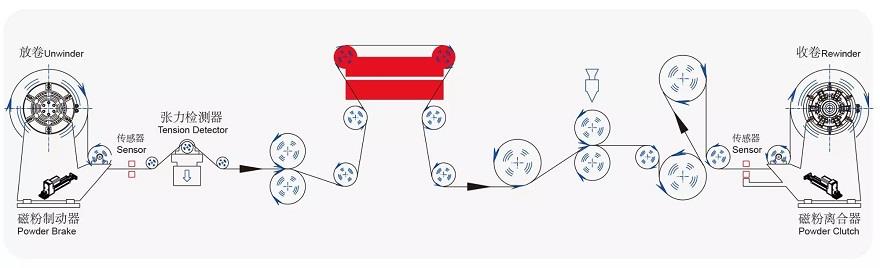

Correction in the modern sense involves a wide range of industries, including packaging, printing, labels, construction materials, pulp, household paper, plastics, garments, cables, metal processing, non-woven fabrics, corrugated paper processing and other industries. A typical correction system includes a correction controller, a correction sensor, a correction frame and a driver.

*Textile machinery: fiber twisters, treatment machines, weaving machines

* Metal fishing systems: extruders, wire stretchers, presses, welders, steel wire retractors, cutters, pipe makers, wire winding machines

*Machine tool systems: lathes,

* Millers, steel extruders, CNC lathes, specialized machinery

* Transportation equipment: hoists, feeders, conveyors, rollers, winders

* Paper- making systems: bag-making machines, box-making machines, slitters, book-making machinery, cutters, copy paper machines

Inquiry

FAQ

1. When can I get the quotation?

We usually quoted within 24 hours after receiving your inquiry. If you are very urgent to get the price, please call us or tell us in your email, so that we can regard your inquiry priority.

2. How should I place the order?

For all in one web guide system, please kind tell us your material max width and which materials, so we will recommend suit model with drawing.

For Servo Linear Web Guide Control System, please kind tell what material and pushing stroke with pushing torque/weight.

For air shaft and roller, please show us your drawing, or let us know your request, and then we will provide you drawing for confirmation.

For powder clutch, powder brake, air clutch, air brake, and safety chucks, please let us know the model number based on our specs.

3. What’s your MOQ basis?

Normally, we don’t have MOQ request, except the rollers.

4. What about the lead time for production?

Honestly, it depends on the order quantity and the type of our products. For powder clutch, powder brake, tension controller, load cell and edge position controller which is about 3-5 days. For safety chucks, air shaft and roller which need about 5-15days

5. What is the term of delivery?

We can arrange with EXW, FOB, CIF…etc. You can choose the most convenient one or cost-effective way.